Other Engineering Projects

FROM ART TO PART - ENGINEERING COMPLEX SYSTEMS INTO REALITY

Jayem Automotives’ design, development and prototyping capabilities extend far beyond on-road vehicles. With deep expertise in engines, structural engineering, electrification and dynamic systems, Jayem has successfully delivered complex engineering solutions across mining, off-highway, industrial, defence and special-purpose machinery.

Backed by in-house casting, machining, fabrication, FRP, assembly, testing and validation, Jayem does not stop at design. Concepts are engineered, built, validated and delivered as working systems enabling faster turnaround times and production-ready outcomes. This integrated approach is what Jayem calls “Art to Part.”

Program Highlights

Dual-Fuel Mining Dump Truck Conversion

A Komatsu HD-785 mining dump truck was retrofitted with an LNG + diesel dual-fuel system, replacing approximately 40–45% of diesel consumption and reducing fuel cost by nearly 15%. The concept was engineered to be scalable across heavy trucks such as Komatsu HD-785 and Volvo FMX 440/460 platforms.

Dump Truck Electric Drive Conversion

A conventional rear axle system was replaced with wheel-end traction motors supported by a planetary reduction system. An alternator-based electric drive architecture was developed, improving efficiency, controllability and suitability for high-load mining applications.

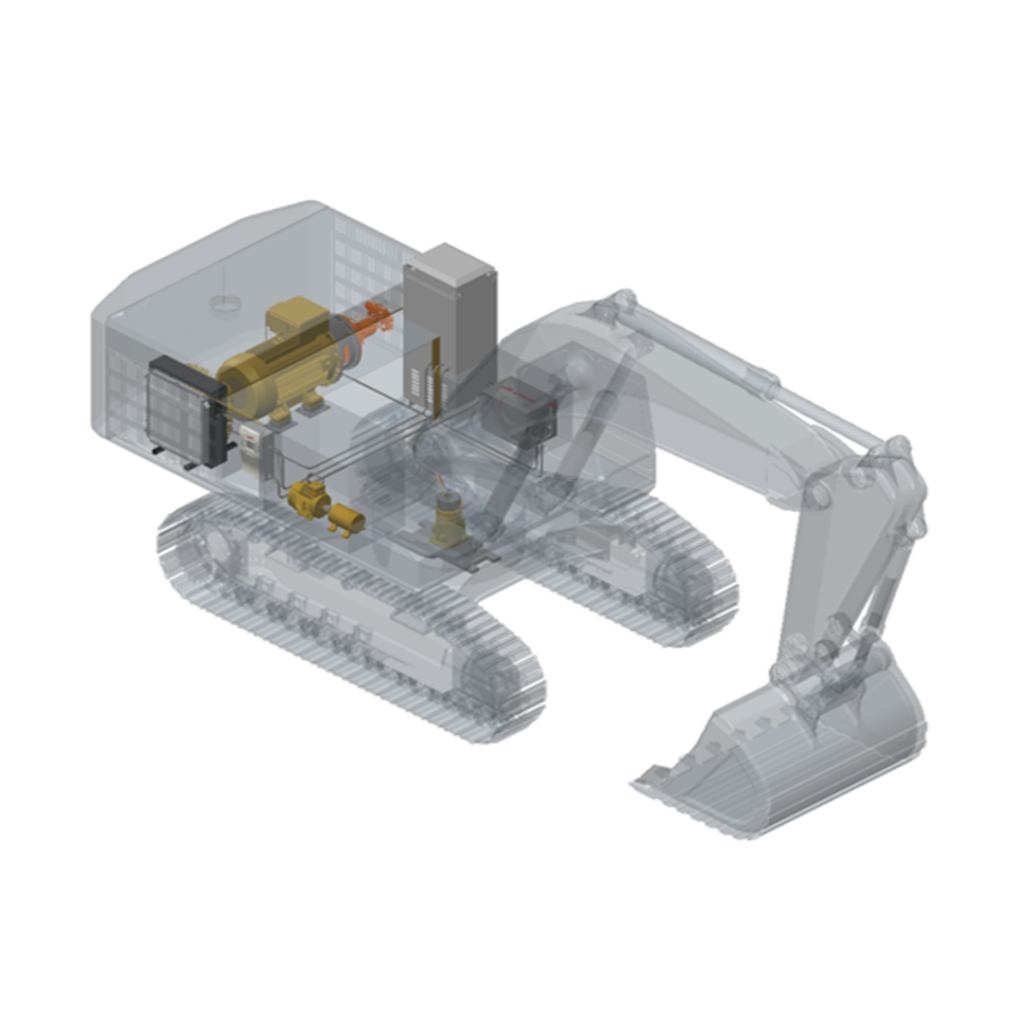

Electrification of Heavy Mining Equipment

Concepts were developed for Komatsu PC300 and Liebherr R996 excavators, converting them to grid-connected electric drive systems. These solutions enable up to 50% reduction in energy cost and 30% reduction in maintenance, making them ideal for mines, indoor operations and low-noise zones. High-voltage cable reeler systems were also engineered as part of the solution.

Electrically Operated Screening Plant

Jayem designed and manufactured the MINEROCK SLS1860, a fully electric mining screen plant delivering up to 800 TPH. The system achieves 15–20% higher productivity and approximately 30% fuel savings, with hybrid diesel-electric power options. The plant is designed for coal, iron ore and bulk material handling.

Special Mining & Industrial Machinery

Engineering solutions were delivered for specialised mining and industrial applications, including excavator-mounted blast hole drill machines, structural lifting systems up to 800-ton capacity, transport-friendly dumper body designs, and chassis scanning with CAD conversion and structural validation.

Excavator & Earthmoving Attachments

Jayem engineered custom excavator buckets, redesigned boom and stick assemblies, and optimised hydraulic cylinders to improve payload, digging force and durability across demanding earthmoving applications.

Mining & Industrial Components

Manufactured components include track pads, grate bars, tooth inserts, forged and machined shafts, gears, pinions, wheel-end drives, remanufactured assemblies, and large steel castings delivered to mining and industrial standards.

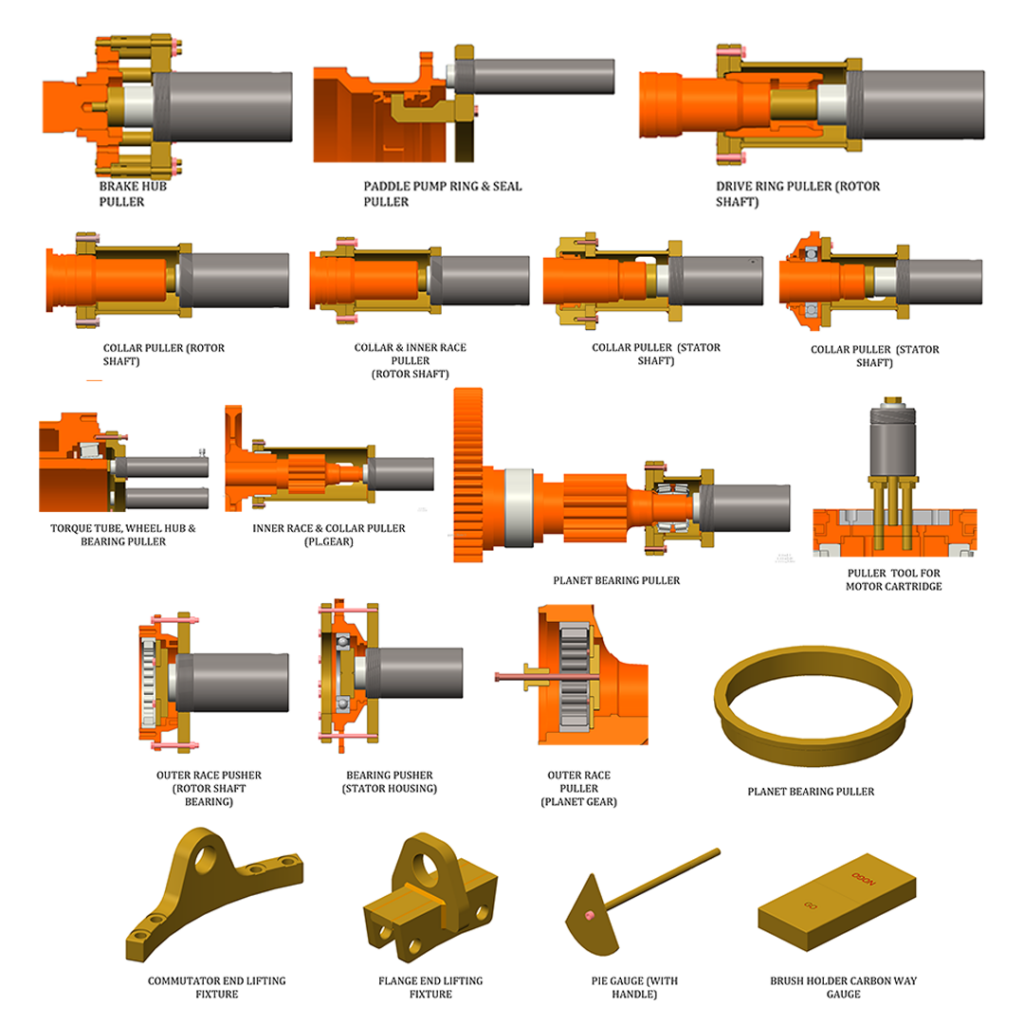

Service Tools & Special Fixtures

A wide range of service tools and fixtures were engineered and manufactured, including engine lifting spreader bars, pump lifting tools, wheel hub and bearing pullers, planet gear tools, motor cartridge tools, and precision gauges supporting heavy equipment assembly and maintenance.

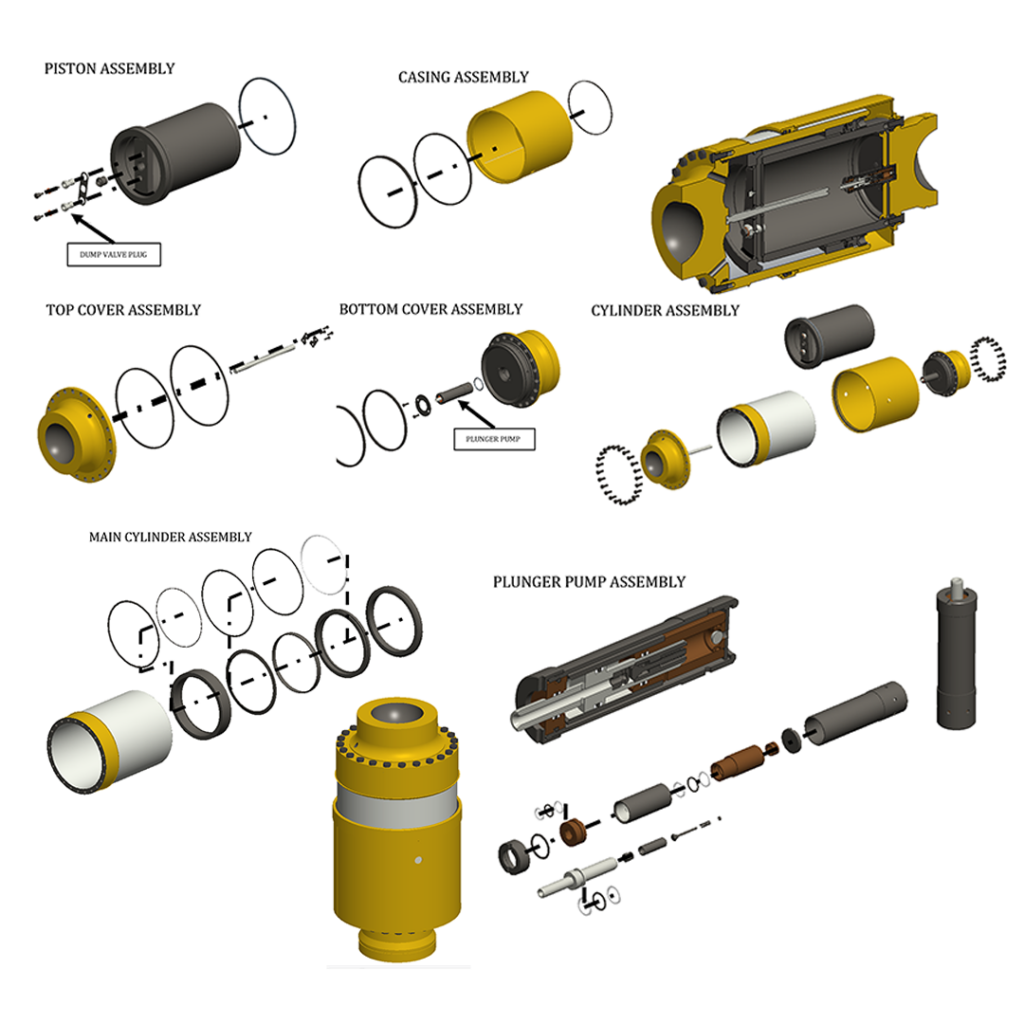

Assemblies & Sub-Systems

Jayem has delivered complex assemblies such as piston-cylinder units, hydraulic suspension cylinders, pump and casing assemblies, and remanufactured dumper wheel-end drives ensuring reliability, serviceability and long operational life.

Precision Components (Non-automotive):

- Gas valve bodies, coupler plates & sleeves

- Industrial gearbox parts

- Grate bar for pellet plants

- Tooth inserts for steel plant gearwheels.