Manufacturing

PRODUCTION-READY SOLUTIONS WITH ENGINEERING PRECISION

Jayem Automotives offers integrated manufacturing services that bridge the gap between engineering and large-scale production. With strong in-house capabilities and decades of hands-on experience, manufacturing is executed with a clear focus on quality, repeatability, scalability, and speed.

Our manufacturing ecosystem supports OEMs, EV companies, and industrial customers—from pilot builds and low-volume production to certified, production-ready systems—while reducing development risk and time-to-market.

Our Manufacturing Portfolio

Drag >>>

Components Manufacturing

Automotive and industrial components are manufactured using a combination of casting, machining, fabrication, FRP, and precision assembly processes. Manufacturing routes are selected based on performance, volume, and cost targets, ensuring consistent quality across proto, low-volume, and series production.

End-to-end control—from design intent to final inspection—allows faster turnaround and improved manufacturability for complex components and aggregates.

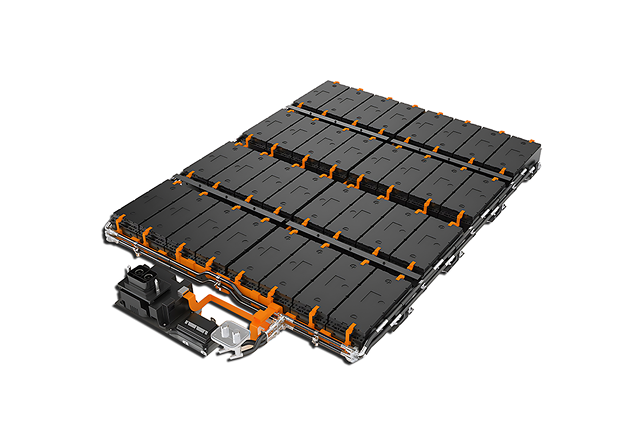

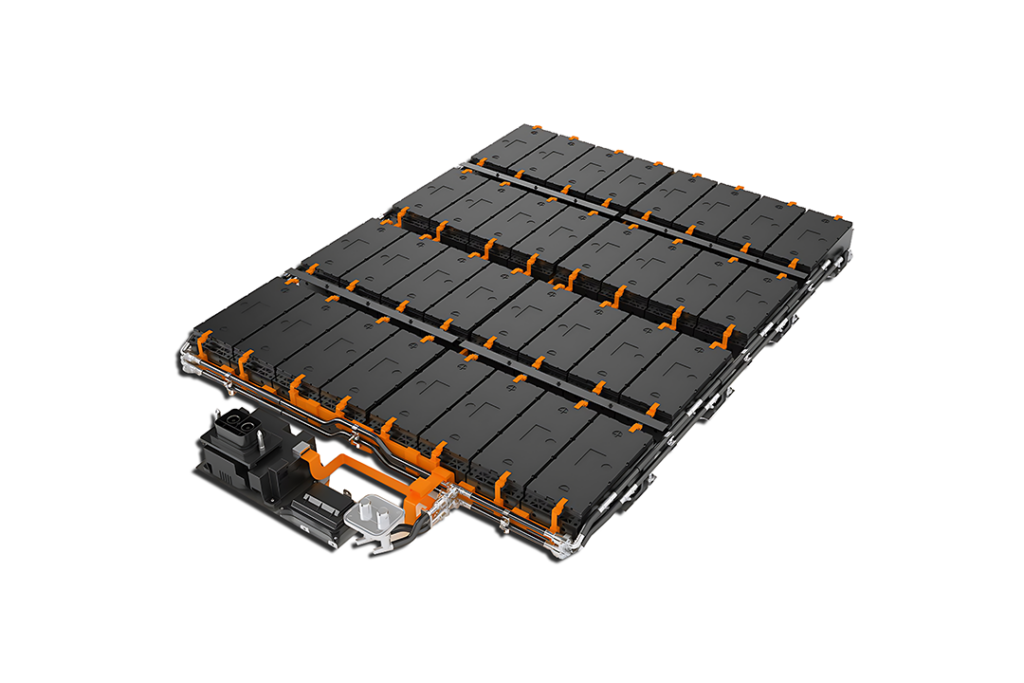

Battery Pack Manufacturing

Battery pack manufacturing is carried out through semi-automated, scalable production lines, supporting EV and energy-storage applications. Pack assembly, integration, and end-of-line testing are executed in-house to ensure safety, reliability, and compliance with automotive standards.

Manufacturing is closely aligned with design and validation teams, enabling faster customisation, smoother homologation, and production-ready battery systems.

Special Vehicles Manufacturing

Special-purpose vehicles and niche platforms are manufactured through dedicated pilot and low-volume assembly lines. This includes EVs, defence vehicles, performance vehicles, and industrial mobility platforms.

The focus is on build quality, system integration, and validation—ensuring vehicles are production-feasible before scaling to higher volumes.

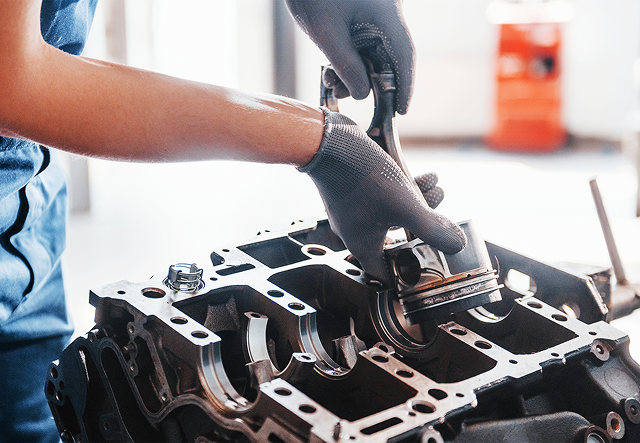

Engine Remanufacturing

Engine remanufacturing restores used engines to as-new performance levels through a structured, industrial process. Complete disassembly, inspection, reconditioning, precision machining, assembly, and testing are carried out to meet defined performance and reliability standards.

This capability supports OEM service programs, fleet operations, and lifecycle cost reduction while aligning with sustainability and circular-economy goals.