About us

About Jayem Automotives

Three Generations of Engineering. One End-to-End Mobility Partner.

Jayem Automotives is a mobility-centric technology company with a legacy that spans nearly nine decades of engineering innovation. Our journey began in 1939, with the development of India’s first electric motor—a milestone that laid the foundation for a culture built on deep technical thinking, hands-on engineering, and continuous innovation.

Over three generations, Jayem has evolved into an independent automotive R&D and manufacturing company delivering design, development, testing, validation, and production-ready solutions for components, systems, and complete vehicles.

What We Do

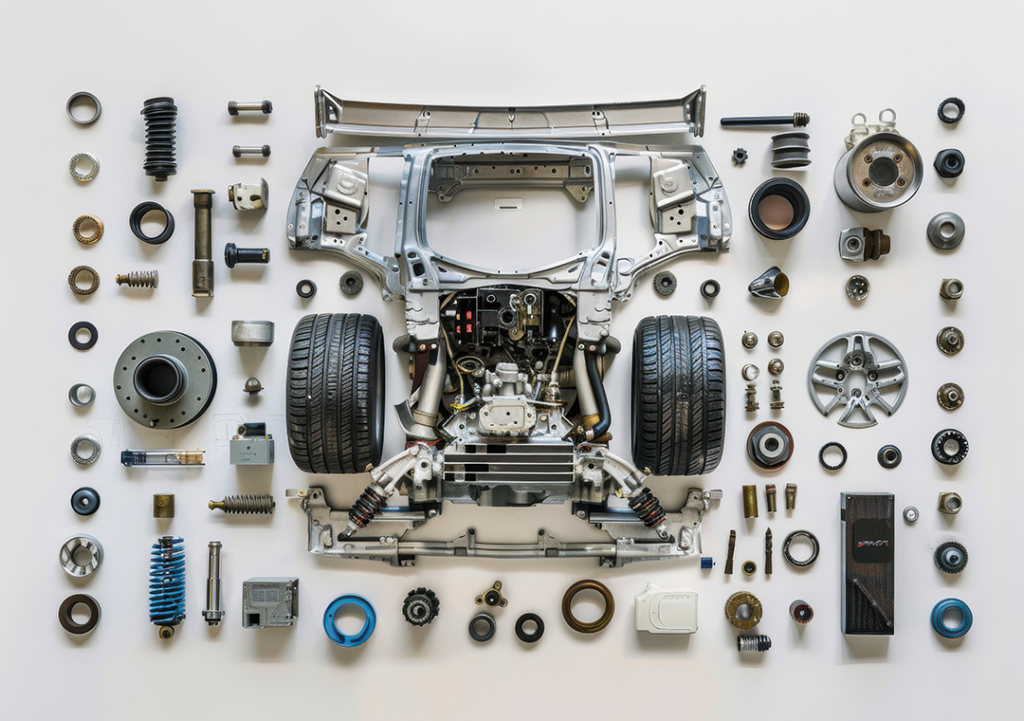

Jayem provides end-to-end engineering, testing, and manufacturing support across automotive and adjacent mobility sectors. Work spans passenger and commercial vehicles, electric mobility, defence and aerospace systems, off-highway and industrial equipment, and special-purpose machines.

Programs are supported through integrated capabilities covering vehicle and system design, powertrain and EV engineering, prototyping, validation, pilot manufacturing, and low-volume production. This breadth allows complex programs to be executed under one ecosystem, reducing dependency on multiple partners and shortening development cycles.

From Art to Part

Engineering at Jayem follows a lifecycle-driven approach where design is closely connected to build and validation. Concepts are developed with clear consideration for manufacturability, testing, certification, and scale-up, ensuring that engineering intent translates smoothly into physical systems.

Engineering at Jayem follows a lifecycle-driven approach where design is closely connected to build and validation. Concepts are developed with clear consideration for manufacturability, testing, certification, and scale-up, ensuring that engineering intent translates smoothly into physical systems

Speed as a Capability

Speed is embedded into Jayem’s operating model. By combining engineering, testing, and manufacturing within a tightly connected workflow, development timelines are compressed without compromising quality or reliability.

Rapid prototyping, parallel execution, and in-house validation support faster decision-making and quicker response to design changes, helping customers accelerate time-to-market while maintaining confidence in performance and compliance.

A New Chapter: Part of the Murugappa Group

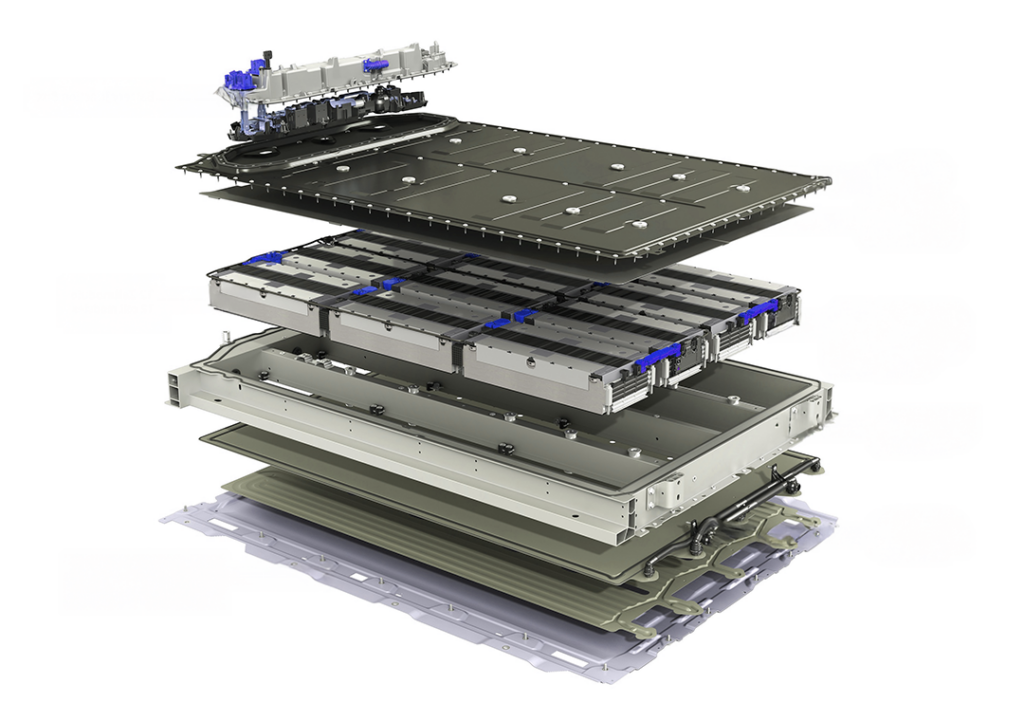

In 2023, Jayem Automotives entered a new phase of growth following its acquisition by the Murugappa Group—through its subsidiary TI Clean Mobility Private Limited. This strategic step strengthens Jayem’s role within the electric and future mobility ecosystem while preserving its engineering-first culture.

The acquisition enables Jayem to scale its engineering programs, expand manufacturing capacity, and accelerate development across electric powertrains, battery systems, and integrated vehicle platforms.

About the Murugappa Group

Founded in 1900, the Murugappa Group is one of India’s most respected and diversified business conglomerates, built on strong governance, long-term value creation, and responsible business practices. The Group operates 28 businesses, of which nine are listed on the NSE and BSE, with a combined revenue exceeding INR 369 billion.

With a workforce of more than 50,000 employees, the Murugappa Group has a strong presence across India and six continents, serving global markets through its leadership in engineering, manufacturing, financial services, agriculture, and mobility. This scale, combined with deep operational expertise, enables sustained investment in technology, talent, and infrastructure across its portfolio companies.

Renowned brands such as BSA, Hercules, Montra, Mach City, Shanthi Gears, Ajax, Chola, Parry’s, Gromor, CG Power and Industrial solutions Ltd. and Ballmaster are part of the Murugappa portfolio.

What This Means for Our Customers

Being part of the Murugappa Group brings greater depth and stability to Jayem’s customer engagements. Customers benefit from enhanced scale, stronger governance frameworks, and long-term investment in engineering, infrastructure, and talent.

This combination of Jayem’s execution-focused engineering culture and the Murugappa Group’s industrial strength enables customers to take on larger, more complex programs with confidence—while continuing to benefit from fast turnaround, flexibility, and end-to-end ownership.

Jayem Today

Jayem stands at the intersection of legacy engineering and modern mobility requirements. Three generations of experience continue to shape an organisation focused on end-to-end delivery, practical innovation, and faster execution.

With integrated capabilities across engineering, validation, and manufacturing, Jayem partners with customers to transform ideas into reliable, production-ready solutions—built with precision, delivered with speed, and supported across the full product lifecycle.

History 1939-1947

History 1930s & 40s

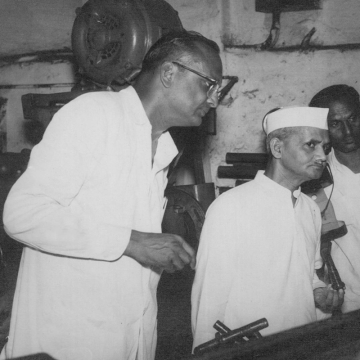

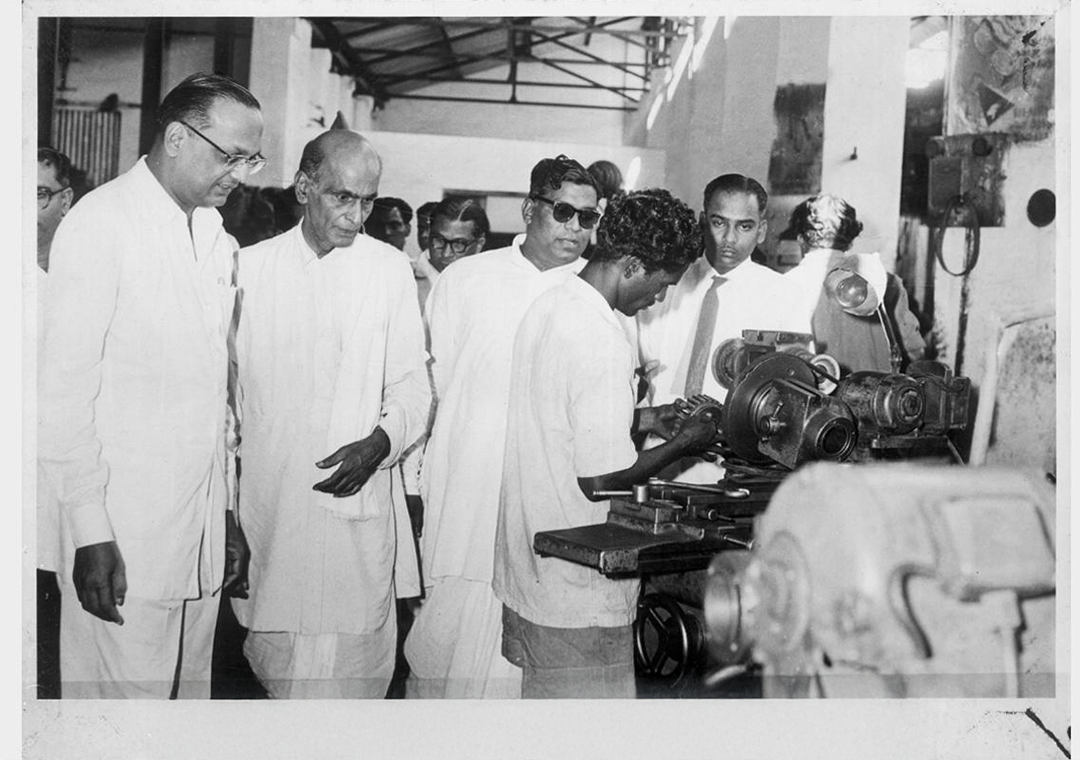

1939 – Mr. D. Balasundaram, a first-generation engineering entrepreneur and the grandfather of the Managing Director, Mr. J. Anand, returned to India after graduating from Sheffield University. India’s first electric motor was developed while he was working as Chief Engineer at Mr. G. D. Naidu’s National Engineering Works.

1939–1946 – The foundation of Textool Company Ltd., India’s first fully indigenous textile machinery manufacturing company, was established.

1947 – India’s first ring spinning frame was developed and productionized, achieving a capacity of 500 tons per month.

1948 – Sten Guns & SBBL 5000 bore guns were manufactured and supplied to the Government.

History 1948-1959

History 1950s

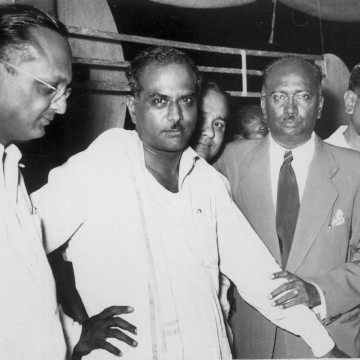

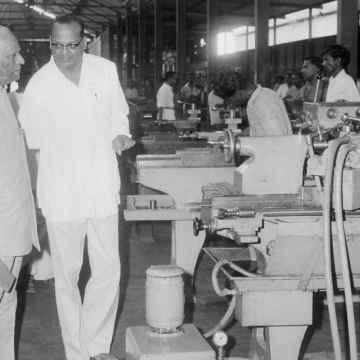

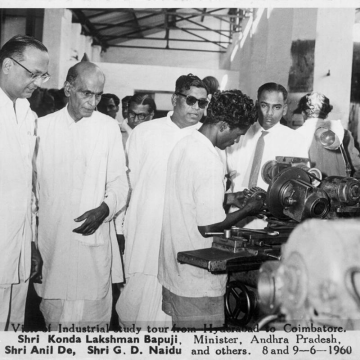

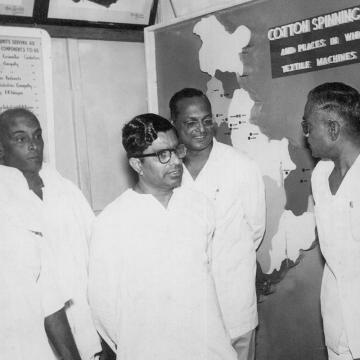

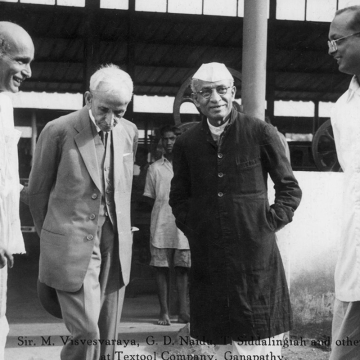

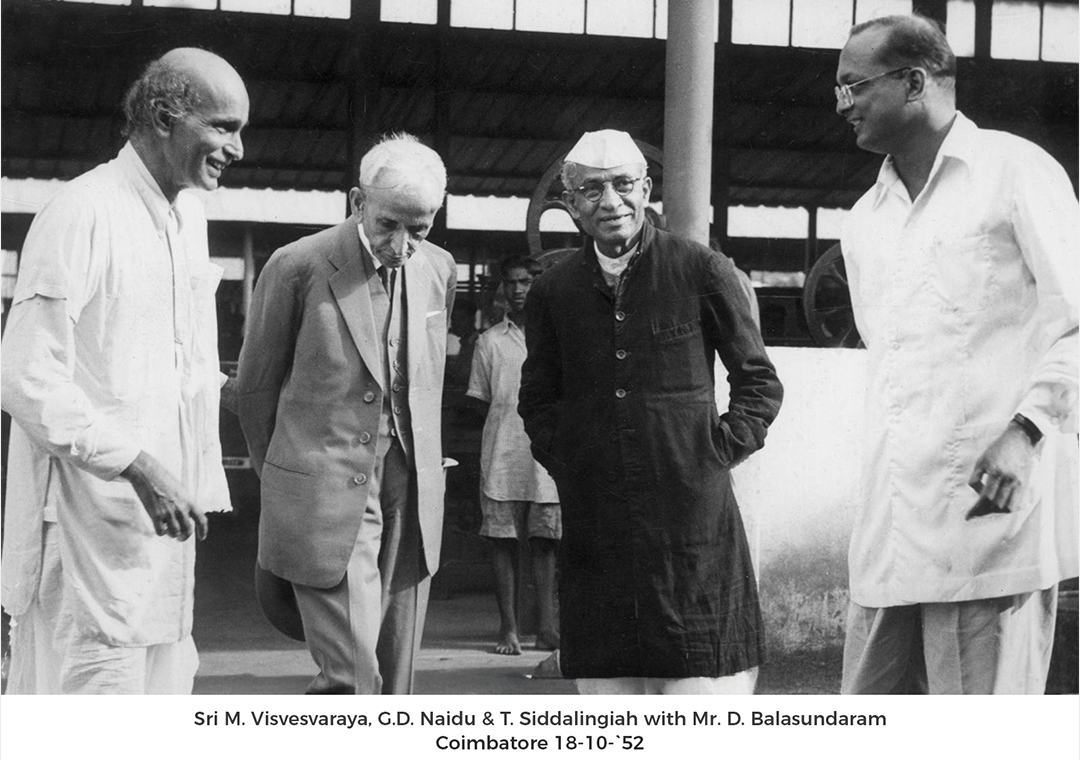

1952 – Textool was visited by Sri M. Visvesvaraya, G. D. Naidu, and T. Siddalingiah along with Mr. D. Balasundaram.

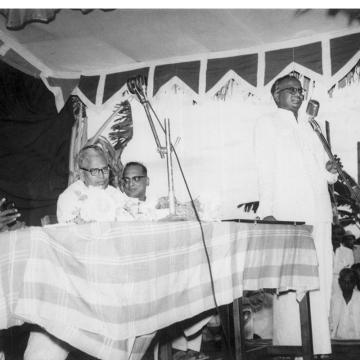

1957 – Textool was visited by Lal Bahadur Shastri, then Union Cabinet Minister for Commerce and Industry.

1958 – A blast furnace with a capacity of 50 tons per day was included in Textool machinery.

1960 – India’s first iron production of Spheroidal Graphite (SG), Iron casting primarily crankshafts for diesel engines were initiated.

History 1960-1969

History 1960s

1961 – Textool was visited by the President of India, V. V. Giri.

1961 – Railway signaling machines and cone winding machines were manufactured with Japanese collaboration.

1964 – Vahan, the first indigenous passenger car, was rolled out from Textool.

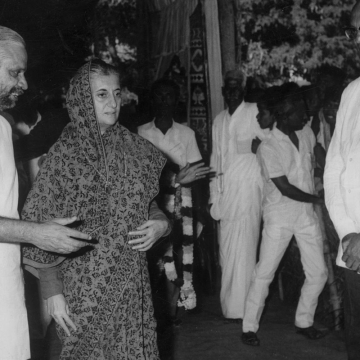

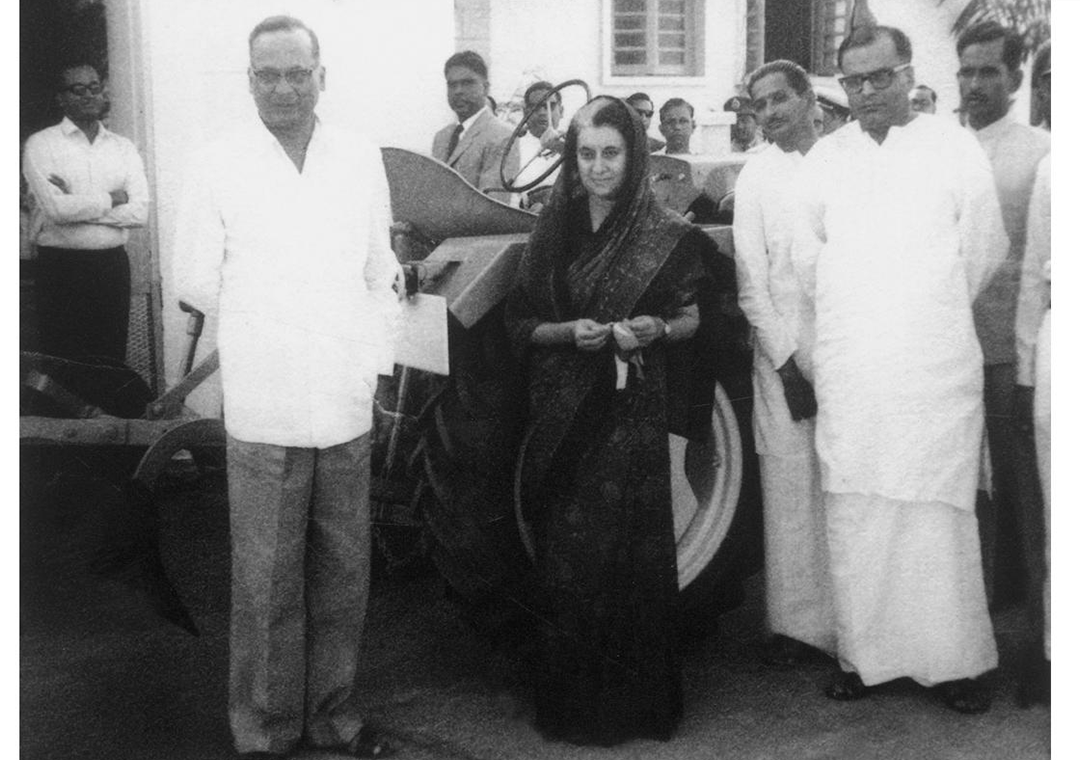

1967 – The first tractor was developed at Textool and was presented to Indira Gandhi for Gujarat relief funds.

1969 – All Tools Private Ltd. was established by Mr. B. Jayachandran, father of Mr. Anand. India’s first indigenous car, tractor, and diesel engine were developed.

A five-ton forklift truck was developed and sold to the Madras Port Trust.

History 1970-1990

History 1970s & 80s

1973 – The two-litre, 4 cylinder diesel engine “Jaya 2000” was developed for Ambassador cars. More than 18,000 engines were manufactured and sold to Ambassador and Premier Padmini vehicles under the brand name “JAYA”.

1979 – The Jaya 1800 overhead cam lightweight diesel engine was developed for Ambassador cars.

1987 – The first 6 cylinder engine was developed for Standard Motor Cars.

1986 – India’s first domestically developed car, Mayura (1500 cc), was showcased at the Auto Expo and received appreciation, including from Shri Rajiv Gandhi.

History 1991-1999

History 1990s

1991 – A lightweight 1350 cc diesel engine for Premier Padmini cars was manufactured for conversion purposes.

1993 – Multi fuel 3 cylinder and 4 cylinder engines were developed with German Elsbett collaboration. The M-11 small car with a 1350 cc diesel engine and the new version of Mayura (M18 – 1500 cc) with a turbocharged multifuel diesel engine were displayed at the Auto Expo.

1995 – The 1350 cc Jaya engine was ARAI certified for emission standards.

1996 – The Formula Mayura racing car was designed.

1997 – The Jaya M1000 commercial three-wheeler and M1000 passenger three-wheeler were developed.

1999 – A new 7-seater three-wheeler with steering wheel was developed for M&M.

History 2000’s

History 2000s

2000 – Jayem Automotives was Incorporated.

2003 – Scorpio-engine NVH issue was resolved by adapting a timing chain drive, eliminating noisy gears.

2006 – The Indica silhouette was developed for the Auto Expo. The development was appreciated by Mr. Ratan Tata and Mr. Sergio Marchionne.

2007 – Improved suspension components for a 3600 GVW bulletproof SUV were developed and integrated.

2008 – A prototype of a Light Strike Vehicle (LSV) with all-four independent suspension was developed. Automatic transmission for a passenger car model was indigenously developed and tested successfully.

2010 – Vista concept “S” displayed in Auto Expo.

History 2010’s

History 2010s

2012 – Jayem’s Coimbatore facility was visited by Shri Ratan Tata for the first time.

2015 – The Tata Bolt sport car was designed, developed, and showcased at the Geneva Motor Show.

2017 – The JTP (Jayem Tata Performance) joint venture was launched. The DRDO Chief visited Jayem and approved the development and supply of aero engine (2.2L common rail diesel engine) for UAV applications.

2018 – ICE to EV conversion for popular car models were designed and developed.

2019 – Under Project Panus, 100 armored vehicles for defence application were manufactured for the Indonesian Government.

2020 – A 230V AC mine screening machine was designed and developed for mining operators.

History 2021-Present

Present

2021 – A 96V e-wheel loader was developed in-house.

2023 – Murugappa group’s TI Clean Mobility acquires stake in Jayem Automotives.

2025 – Electric Small Commercial Vehicle (e-SCV) designed & developed by Jayem, was launched in Bharat Mobility Expo under Montra Electric brand.