Components Manufacturing

Precision Parts. Scalable Production. Proven Engineering.

Jayem Automotives is a vertically integrated components manufacturing company in India, delivering proto, low-volume, and production parts across automotive, EV, defence, mining, oil & gas, textiles, and industrial machinery. With in-house design, foundry, machining, fabrication, FRP, paint, and integration shops, we control quality, lead time, and cost—end to end.

ISO 9001:2015 certified facilities and world-class processes enable us to manufacture complex components with speed, consistency, and reliability.

What We Manufacture

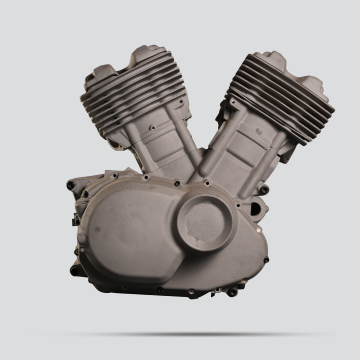

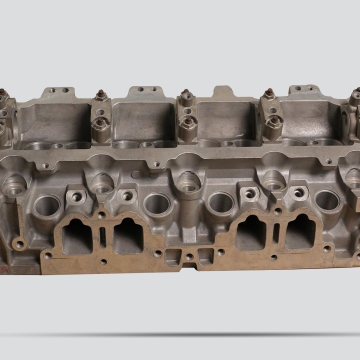

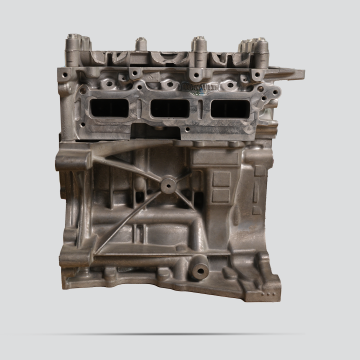

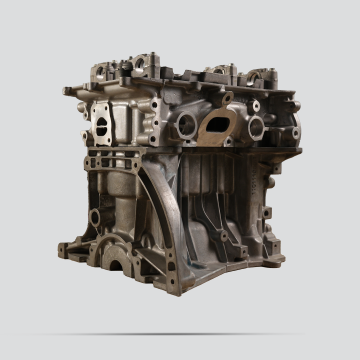

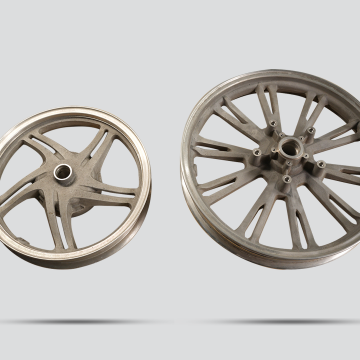

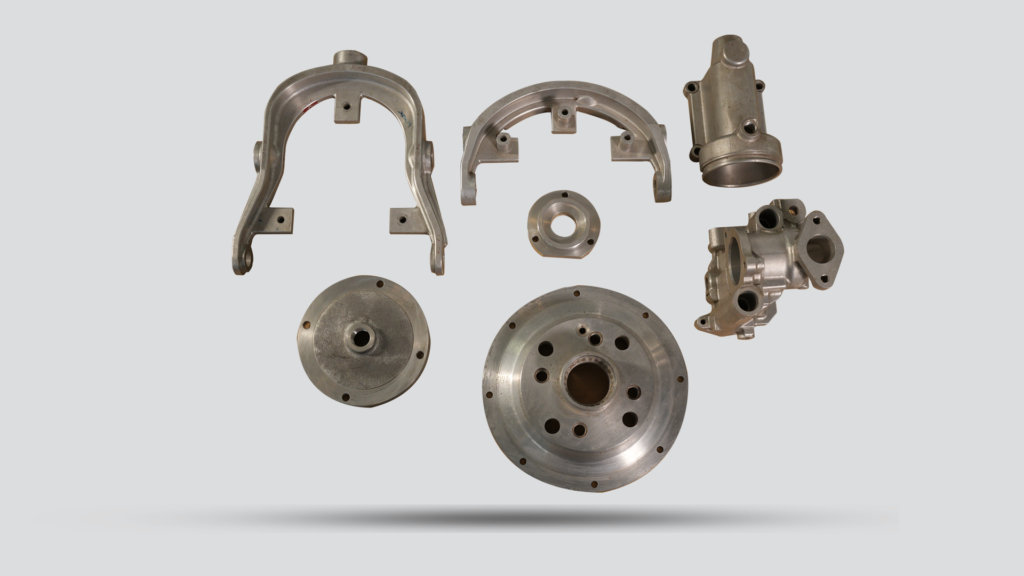

Automotive & EV Components

A wide range of automotive and electric vehicle components are manufactured to meet performance, durability, and regulatory requirements. These include cylinder heads and blocks, head covers, camshaft carriers, intake manifolds, clutch and transmission housings, valve bodies, timing covers, thermostat housings, crankshafts for one- to four-cylinder applications, axle housings, and brake drums and discs.

Electric mobility programs are supported through the manufacture of EV motor housings, front and rear covers, and battery enclosures, along with structural parts such as two-wheeler frames, bridge frames, and pivot housings.

Performance, Defence & Specialty

Components are also manufactured for high-performance, defence, and specialty applications where strength, accuracy, and reliability are critical. This includes suspension parts, exhaust manifolds, and space-frame chassis for formula and race cars, as well as armoured turrets and defence hardware supplied for international programs. Motorsport accessories and race-car components are produced with close attention to weight, stiffness, and repeatability.

Industrial & Heavy Engineering

Jayem supports industrial and heavy engineering sectors with components for mining, earthmoving, oil and gas, textile, and steel plants. Manufacturing includes mining wear parts such as track pads, grate bars, and tooth inserts; valve bodies, coupler plates, and sleeves for oil and gas applications; swivel joints and suspension systems for earthmovers; and gearbox components, pulleys, and grates for textile and steel plant machinery.

Manufacturing Capabilities

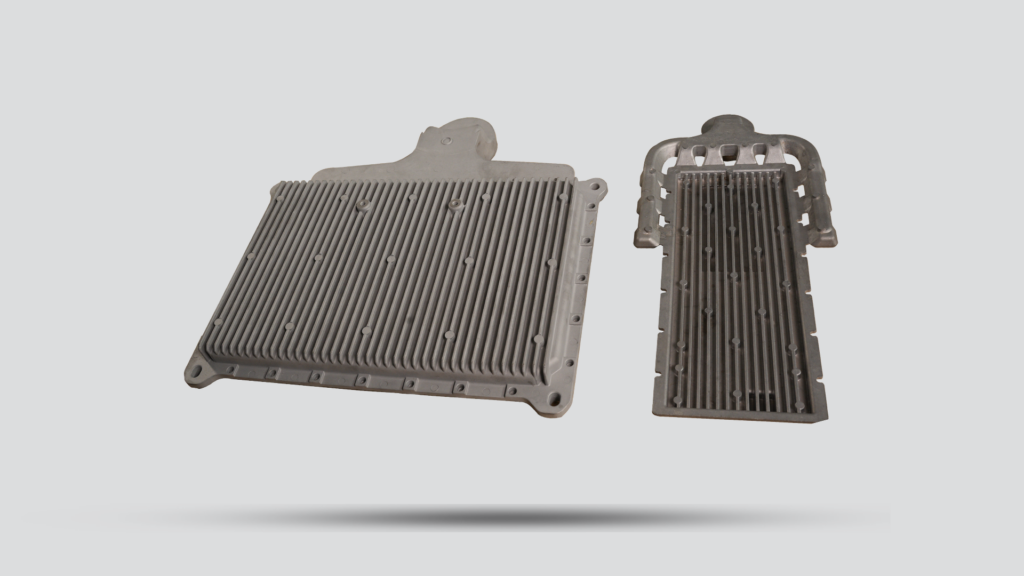

Casting (Ferrous & Non-Ferrous)

Casting operations cover both aluminium and ferrous materials, supporting sand casting, gravity die casting, low-pressure die casting, and high-pressure die casting. Aluminium and ferrous castings are produced in grey iron, ductile iron, alloy iron, and steel grades, with typical part weights ranging from 100 grams to 196 kilograms and sizes up to 1,600 mm. Automated gravity die casting, core shooting, spectrometer-based material verification, and casting simulation are integrated into the process to ensure consistency and quality.

Machining

Machining is carried out using a wide range of CNC equipment, including VMCs, HMCs, VTLs, turning centres, and precision grinding machines. Capabilities include machining of castings, billets, and forged billets in aluminium, steel, alloy steel, brass, and copper. Tool pre-setters, balancing machines, and in-process inspection systems support dimensional accuracy and repeatability across volumes.

Fabrication & Sheet Metal

Fabrication and sheet metal operations include laser cutting, CNC gas cutting, presses up to 250 tonnes, and multiple welding processes such as MIG, TIG, arc, gas, and spot welding. Pipe bending, shearing, and forming are carried out to support structural and tubular components.

FRP & Paint

FRP components such as bumpers, dashboards, wheel arches, and gear consoles are manufactured alongside wet paint and finishing facilities, enabling complete component delivery.

Tooling & Patterns

Tool and die design, pattern making, and proto tooling are supported in-house, allowing faster development cycles and better control over casting and fabrication quality during prototype and production phases.

From Design to Delivery

Component manufacturing at Jayem is supported by integrated design and development capability. Components and sub-assemblies are designed with manufacturability, durability, and performance in mind, supported by CAE and CFD analysis for strength, fatigue, and thermal behaviour. Rapid prototyping, including laser sand sintering, is used to accelerate validation.

Production routes are selected based on application requirements and include sand casting followed by machining, gravity die casting with secondary machining, pressure die casting for brackets and mounts, billet machining for covers and housings, and sheet metal or structural fabrication for cross members and suspension components.

Quality & Inspection

Quality assurance is embedded throughout the manufacturing process. Dimensional inspection is carried out using advanced metrology systems including CMMs from Zeiss and Sheffield, surface finish testers, 2D video measurement, and profile scanning against 3D CAD data.

Material integrity is ensured through chemical composition analysis, microstructure evaluation, and mechanical testing such as hardness, tensile, yield, elongation, fatigue, bend, torque, compression, and stiffness testing. Non-destructive testing including ultrasonic testing, liquid penetrant inspection, magnetic particle inspection, and radiography is performed, along with cleanliness and gravimetric dust analysis. All operations are certified to ISO 9001:2015 standards.

Sector Coverage

Jayem’s components manufacturing supports two-wheelers, three-wheelers, passenger vehicles, and commercial vehicles, as well as defence and aerospace programs, motorsport and performance applications, mining and earthmoving equipment, oil and gas systems, textile machinery, steel plants, and general industrial equipment.