Engineering

TURNKEY SOLUTIONS FROM CONCEPT TO LAUNCH.

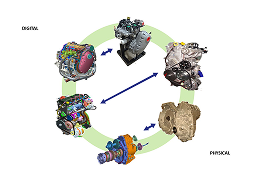

Jayem Automotives partners with OEMs, EV and new-mobility companies as a full-stack vehicle engineering services provider, supporting programs from early concept definition to production-ready pilot builds. Vehicle architecture, system integration, validation, and industrialisation are handled under one roof—enabling faster development, lower risk, and smoother transition to SOP.

With in-house design, CAE, prototyping, testing, and pilot manufacturing, development cycles are compressed, engineering and tooling costs are optimised, and manufacturability issues are addressed early in the program lifecycle.

Our Service Portfolio

Drag >>>

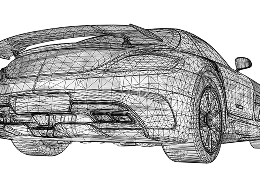

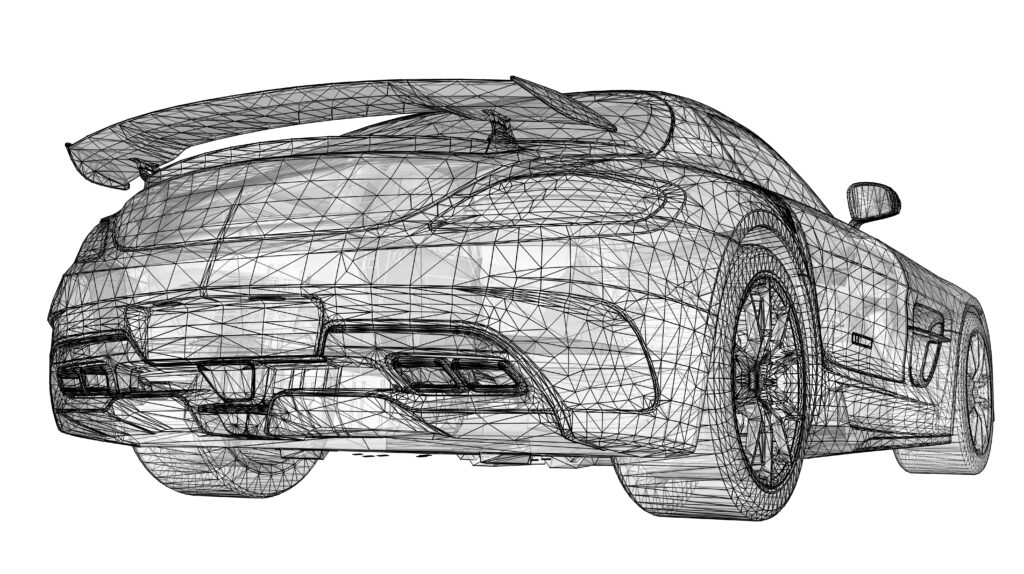

Vehicle Concept Design & Architecture

Vehicle design and concept development are carried out with a strong focus on feasibility, packaging, and downstream manufacturability. Styling feasibility, vehicle architecture, and layout studies are developed to ensure concepts can be translated into real, buildable vehicles while meeting performance, regulatory, and cost targets.

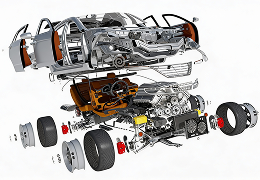

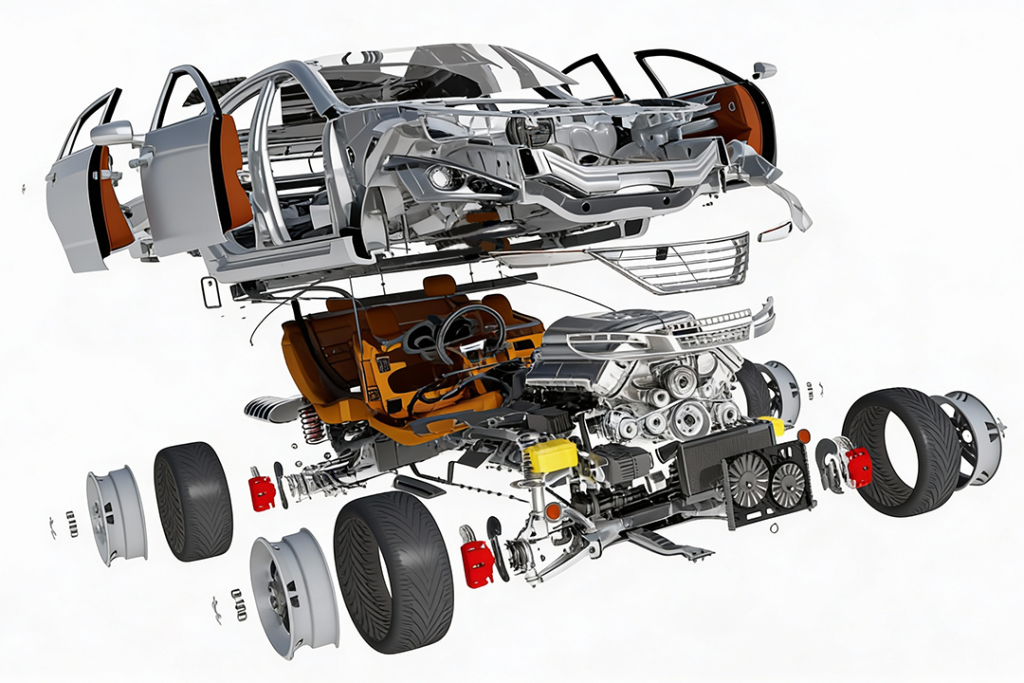

Complete Vehicle Engineering

Complete vehicle engineering is delivered by integrating all subsystems into a cohesive, production-ready platform. Mechanical, electrical, electronic, and software systems are engineered, packaged, and validated to ensure functional compatibility, performance compliance, and reliability across vehicle programs.

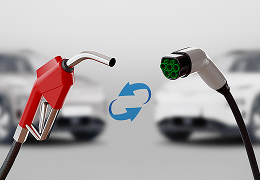

Alternative Drivetrain Engineering & Integration

Alternative drivetrain systems are designed and integrated to suit electric, hybrid, and new-energy vehicle architectures. With over 25 years of experience in EV conversions from ICE platforms, drivetrain integration is carried out holistically—covering motors, inverters, batteries, cooling systems, and controls—ensuring optimal vehicle performance and safety.

Module and System-Level Engineering

Vehicle modules and systems are developed as standalone units with defined interfaces for easy integration. Structural, functional, and safety requirements are addressed at the module level to reduce system complexity and improve development efficiency across multiple vehicle platforms.

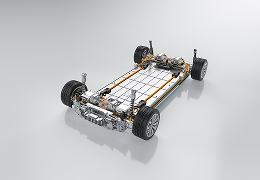

Vehicle Platform Solutions

Scalable vehicle platform solutions are engineered to support multiple derivatives across segments. Architecture standardisation, modularity, and reuse are prioritised to reduce development time, optimise cost, and enable faster product launches across OEM portfolios.

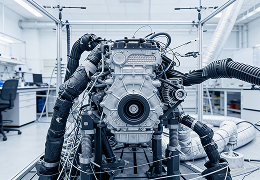

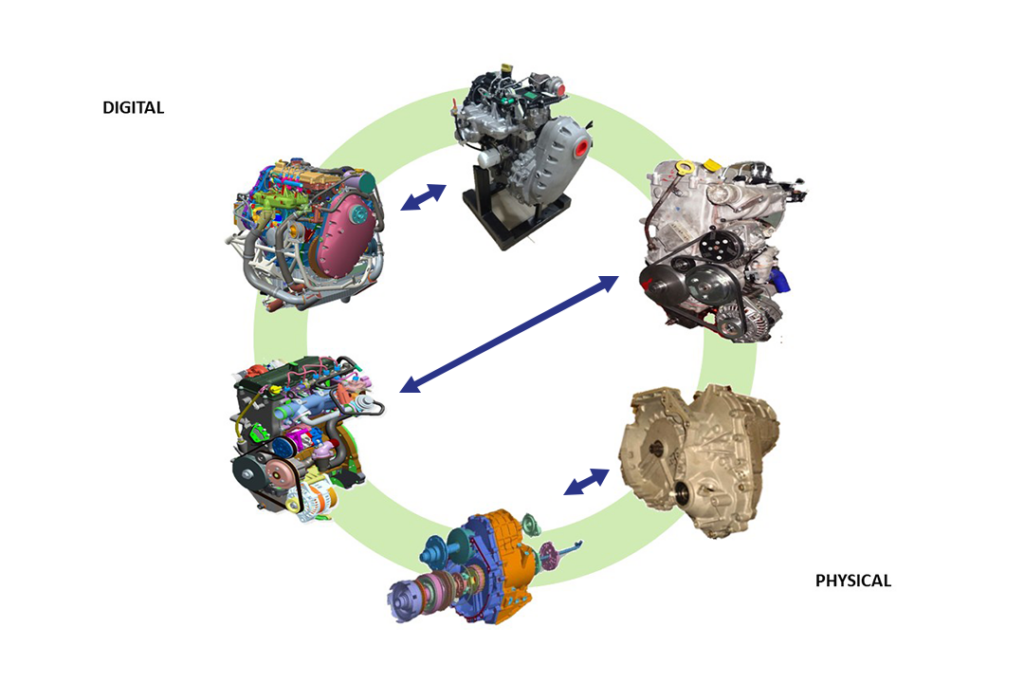

Advanced Powertrain Engineering

Powertrain engineering services cover engines, transmissions, electric drivetrains, and hybrid systems. Design, development, calibration, testing, and validation are executed to meet performance, efficiency, emission, and durability targets across automotive and mobility applications.

Prototype Development & Pilot Manufacturing

Prototype and low-volume builds are executed to validate design intent, manufacturing feasibility, and system integration. Pilot builds support design freeze, supplier validation, and early market testing before scaling to series production.

Performance, Durability and Validation Testing

Vehicle testing is conducted across lab, track, and real-world conditions to validate performance, durability, safety, and regulatory compliance. Testing data is used to refine designs, derisk production readiness, and ensure robust vehicle performance throughout the product lifecycle.

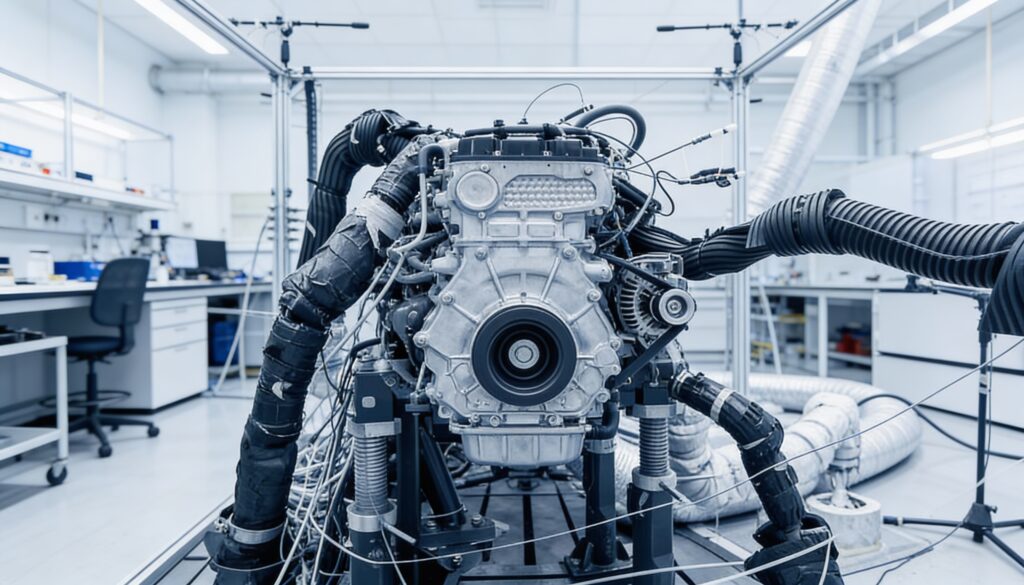

Aero Engine

Indigenous diesel aero engine systems for tactical and MALE UAVs are developed on a proven 2.2-litre inline four-cylinder platform, comprising a 180 hp production engine and a 220 hp prototype optimised for heavy-fuel, long-endurance missions. Lightweight construction, an integrated propeller reduction gearbox, and a redundant FADEC system are incorporated, with validation carried out through extensive bench and altitude testing. Integration on the TAPAS UAV, including ground and taxi trials, has demonstrated reliable high-altitude performance while supporting faster development cycles and reduced program risk for defence and civil UAV platforms.