Battery Pack Manufacturing

Scalable, Certified, Future-Ready Energy Systems

We design, manufacture, and supply tailor-made battery systems for automotive, industrial, and grid applications—enabling rapid go-to-market and premium value, aligned with Make in India and global quality standards.

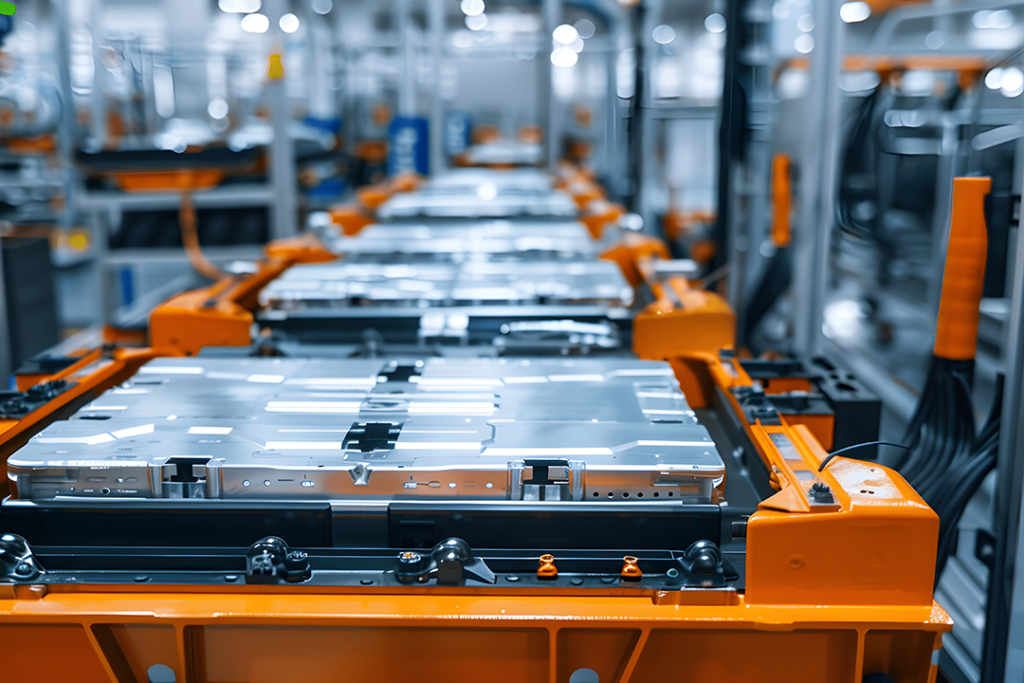

Our Battery Manufacturing Facility

Battery packs are manufactured at Jayem’s dedicated facility located in Coimbatore, spread across 12,000 square feet and designed as a semi-automated assembly line. The plant has an installed capacity of 150 MWh, with provision to scale up to 300 MWh within the same facility, supporting future program growth without infrastructure disruption.

The facility is engineered for safety, quality, and efficiency, with controlled material flow and traceability embedded across operations. Cell handling is carried out within ISO Class 7 cleanroom environments, ensuring contamination control and consistent quality. Semi-automated module and pack assembly lines are supported by bidirectional cyclers that enable simultaneous charge and discharge, reducing grid power consumption. Comprehensive End-of-Line (EOL) testing is conducted to ensure every battery pack meets defined performance and safety benchmarks before dispatch.

End-to-End Battery Solutions

We deliver a one-stop solution—from concept to certification:

Design & Engineering

Battery pack design and engineering are carried out to support both low-voltage and high-voltage systems, with pack architecture tailored to application-specific requirements. Engineering focuses on structural integrity, thermal management, electrical safety, and serviceability, ensuring seamless integration with vehicle and system platforms.

Multiple cell chemistries and form factors are supported, enabling flexibility across passenger vehicles, commercial vehicles, and industrial applications. Packaging is customised to suit space constraints, duty cycles, and regulatory requirements.

Manufacturing

Battery manufacturing includes module and pack assembly executed through semi-automated processes designed for consistency, speed, and repeatability. Assembly processes are validated to ensure dimensional accuracy, electrical integrity, and mechanical robustness.

Process traceability is maintained throughout manufacturing, enabling quality control, audit readiness, and lifecycle support. The manufacturing setup supports pilot builds, low-volume production, and scale-up for series programs.

Testing & Validation

Testing and validation are integral to Jayem’s battery pack manufacturing approach. In-house cell and pack testing laboratories support electrical, thermal, mechanical, and safety validation across development and production stages.

Pre-homologation testing is carried out internally to enable first-time-right certification, reducing approval timelines and development risk. Validation processes ensure compliance with automotive standards and customer-specific performance requirements.

Certification

Jayem supports battery pack type-approval and certification as part of its end-to-end offering. Engineering and testing teams work closely with certification agencies to ensure compliance with applicable standards and regulatory requirements, enabling smoother homologation and faster market entry.